Many biological or chemical experiments involve a wide range of concentrations, and serial dilution is a common technique used in such cases. Just like direct dilution, it’s crucial to ensure accurate pipetting volumes. However, mistakes can easily occur during the multiple pipetting steps involved.

No matter your methods or throughput, we offer automation that fits your lab. Watch our on-demand webinar on How to Choose the Right Automation for Your Lab to learn which platform makes the most sense for you.

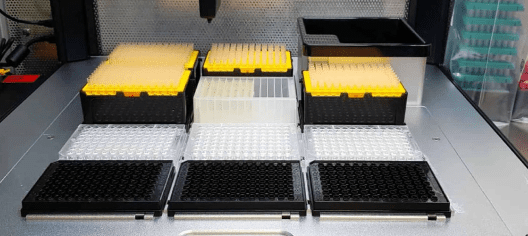

Opentrons helps you automate serial dilution with open-source protocols for the OT-2 and Opentrons Flex

Our team of experts can help figure out if automation is right for you. Book a virtual demo to discuss your workflow needs with an expert.