The next generation of chemists will need automation in the lab. The Greenaway lab and their colleagues at Imperial College London know this better than anyone. They’ve implemented not one, but two, courses with automation to provide students with the tools to move into tomorrow’s chemistry careers.

As a part of the Opentrons for Education initiative, we’re speaking with educators like Becky Greenaway, Annabel Basford, and Sean Gurung to take an in-depth look at how they’re using Opentrons liquid handling robots in their classrooms.

Courses at-a-glance

| Course | Automation in Chemistry, Drug Discovery, and Materials | Emerging Technologies |

| Level | MSc students | Undergraduate students (chemistry) |

| Class Time | • Full term (10 weeks) • 7 hours of automation over 2 lab sessions | • Full academic year • 2 weeks of automation lab time |

| Number of students | Up to 25 students | 30 students |

| Student per robot | 2-4 students per OT-2 | 5-6 students per OT-2 |

| Automation on the OT-2 | Universal indicator development, acid-base pH titrations, and measuring pH | Automated batch synthesis and a mini-project in automation |

Educator Profiles

Becky Greenaway is a senior lecturer at Imperial College London. She is also a co-founder and automation lead in the Institute for Digital Molecular Design and Fabrication, or DigiFAB. DigiFAB is an interdisciplinary center where chemistry, big data, and automation meet, with the goal of supporting and enabling new methods of chemical and drug discovery.

Becky received an MChem in Chemistry from the University of Sheffield and a Ph.D. in Organic Chemistry from the University of Oxford. As a postdoctoral fellow working on molecular organic materials at the University of Liverpool, Becky began using automation herself. She brought her Royal Society University Research Fellowship to Imperial College London in 2020.

Today, Becky’s research group focuses on organic synthesis, supramolecular chemistry, porous materials, and automation in chemistry. Discovery and characterization of new molecular organic materials is critical, but time- and labor-intensive. Becky and her team work to develop high-throughput automated approaches to improve and accelerate the process.

Annabel Basford is a Ph.D. candidate and researcher in the Greenaway lab at Imperial. Her research focuses on automating reaction screening for supramolecular organic assemblies. Opentrons equipment in the lab has allowed her to automate the synthesis, high-throughput characterization, and data analysis throughout the process of organic materials discovery.

Annabel received an MChem in Chemistry from the University of Manchester. She actively sought out a graduate program that would allow her to combine her interests in computational approaches and chemistry at the bench, and found it at Imperial. She is co-advised by both Becky and Prof. Kim Jelfs in a combination program, where Annabel obtained a second MRes in Advanced Molecular Synthesis.

Since 2021, Annabel has taught students from undergraduate to postgraduate levels in topics like Python, data analytics, and machine learning in chemistry. Her work helped lay the foundations of Opentrons automation in the Greenaway lab, their department, and even the classroom.

Sean Gurung is a Ph.D candidate and researcher in the Greenaway lab at Imperial. As a part of Alchemy, the UK’s new national hub for AI in chemistry, his research centers on creating fully autonomous and applicable chemistry workflows.

Sean began working with the Opentrons OT-2 at Imperial during his MRes in Advanced Molecular Synthesis. His work focused on automating the synthesis of novel heteroaromatic photoswitches. A continuing interest in high-throughput automation for chemistry led him to pursue a Ph.D. at the university, where he’s co-advised by Dr. Alex Ganose and Prof. Kim Jelfs.

As an early Ph.D. student at Imperial, Sean is continuing his work at the emerging intersection of AI and chemistry. With access to equipment like the Opentrons Flex, his research will expand on the Greenaway lab’s previous work by adding AI-driven decision-making to achieve truly autonomous workflows.

Automation and chemistry: forward thinking

Research like the Greenaway lab’s is often labor and time-intensive. Automation can help increase throughput, efficiency, and precision, all while saving valuable time at the bench. In Becky’s new lab at Imperial, the open-source Opentrons Python Protocol API made for a natural and flexible fit. As chemists, variance in solvents, reagents, and experimental procedures are a natural part of everyday workflows. In the lab, “the available API provides us with the control and flexibility we need,” Sean explains.

As the first graduate student to work on automation in Becky’s lab, Annabel set up their OT-2 liquid handling robot for supramolecular chemistry workflows. Despite having no previous experience in automation, encouragement from Becky made a difference. “This just shows that if I can go in with no experience and … come out like this, then lots of other students can as well,” Annabel recalls of her early graduate work. Today, the Greenaway lab has expanded their chemistry workflows on the OT-2 in collaborative projects to include synthesis of photoswitches, late-stage functionalization of pharmaceuticals, and metal–organic cage assemblies, along with everyday sample preparation for nuclear magnetic resonance (NMR) and mass spectrometry.

Translating their automation work into the classroom was a natural next step. “Chemistry at Imperial has always been very forward-thinking,” Becky says. As an institution, Imperial values hands-on, real-world experience for their students, including cutting-edge techniques like artificial intelligence and machine learning. Their chemistry program already includes Python courses for first-year students, building the foundation for students to gain new skills in automation.

As industry labs move towards automation, students need new experiences relevant for the evolving job market. Although automation in the lab or classroom can feel like a large step for educators, “There’s a difference between what automation looks like and what it actually is,” Sean says. “It looks like a big barrier, but working towards it, it doesn’t look bad at all. It becomes relatively simple.”

At Imperial, Becky and Annabel first developed a postgraduate course, designed as part of a fully online master’s program. Students pursuing an MSc in Digital Chemistry with AI and Automation could remotely access automation resources at the university from anywhere in the world. Based on the success of their first course, their lab developed a fully on-campus postgraduate and undergraduate course, allowing students to experiment with automation and complete independent research projects in person.

Students take the lead: a postgraduate course

Students pursuing an MSc in Digital Chemistry with AI and Automation work with the Opentrons OT-2 liquid handling robot as part of the Automation in Chemistry, Drug Discovery, and Materials module. As the module lead, Becky teaches up to 25 postgraduate students per year in automation techniques. While students receive an introduction to Python programming at the start of the course, not every student begins the program with Python experience. Using the no-code Opentrons Protocol Designer can help bridge the gap in the classroom, and by the end of the term, students gain experience in automating their own scripts for their experiments.

Students work in small groups of two to four with the OT-2 to complete tasks like translating the batch procedure for making universal indicator into an automated protocol, carrying out acid-base pH titrations, and then measuring pH with an integrated robotic arm and probe. In a typical week, students are given time to write scripts for both the OT-2 and the robotic arm ahead of carrying out their automated measurements. “The aim is to provide [students] with experience [in] translating conventional chemical batch synthesis into an automated protocol,” Becky says.

After learning how to use the OT-2 in the course, some students choose to carry out a prototyping project. Working with Becky and Dr. David Miller from the Imperial Advanced Hackspace, students develop low-cost custom modules to integrate with the OT-2, enhancing its organic synthesis capabilities.

Building an automation foundation: an undergraduate course

Third year chemistry undergraduate students at Imperial can also gain experience with automation in the Emerging Technologies laboratory course. Each student begins the course with Python and wet-lab experience, but are introduced to different enabling technologies including automation (using the OT-2), flow chemistry, and mechanochemistry, before then gaining hands-on experience with one of these techniques.

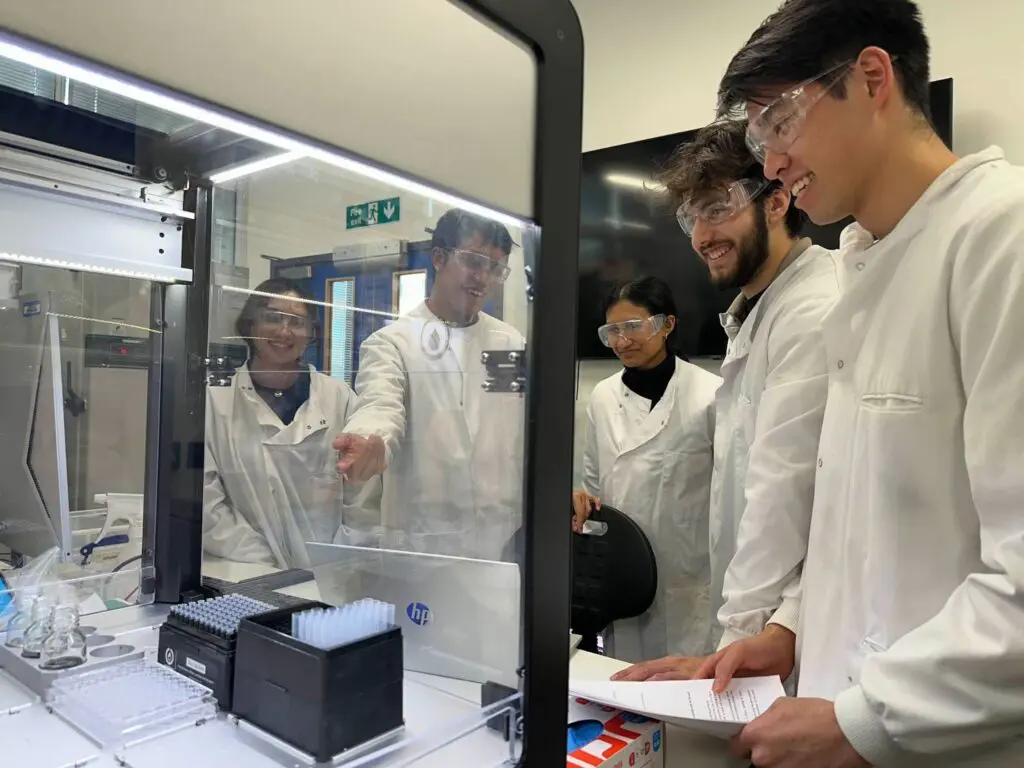

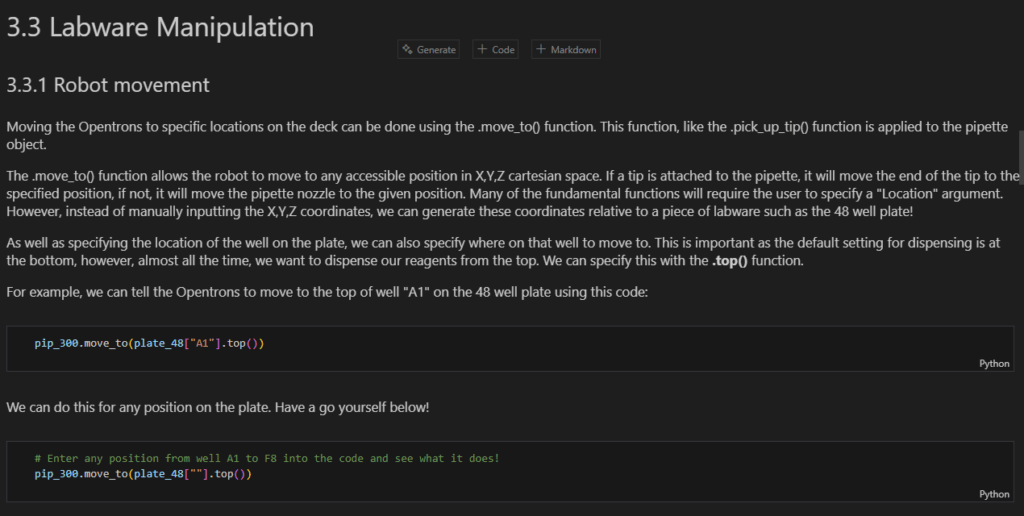

In the course, groups of five or six students work with the Opentrons OT-2. A step-by-step guide using a Jupyter notebook, developed by Sean, gives students their first opportunity for real-time robot operation. Here, concepts are directly aligned with code samples to allow students to gain familiarity with loading labware, basic robot controls, and setting advanced liquid handling settings.

Their tutorial takes advantage of the Jupyter notebook for “quick feedback between writing code and seeing the changes,” Sean says. Students run code on the robot directly from a connected computer and can test their knowledge of new concepts as they learn to use the OT-2.

Throughout the term, students should “come away with an awareness of the techniques you can use that aren’t just conventional synthesis,” Becky explains. Students compare and contrast a manual and automated batch synthesis in the lab, then design and carry out a mini-project to test the automation concepts taught across the course. Examples might include studying the kinetics of an automated reaction on the OT-2, designing custom 3D-printed labware, or comparing Python protocols written by OpentronsAI to those manually written by students.

Given the success of the course, Becky and her lab aim to automate more processes on the OT-2. During an automated chemical synthesis, “students might make a small molecule or polymer, and would identify their results with infrared spectroscopy (IR) and NMR,” Annabel explains.

Results and impact

Developing multiple courses has given Becky and her lab a unique insight into the impacts on their students. Although their online postgraduate course was especially suited for online learning during the pandemic, moving the course in-person has increased student confidence. “You can see their confidence growing from the start of the lab to the end of the lab,” Annabel says. The students’ interest also leads to questions about the Greenaway lab’s work, and excitement about what other experiments can be automated.

An unexpected result? Automation can save researchers valuable time, not just on the laboratory bench, but in the classroom. Implementing further course integrations, like a robotic arm to automatically measure the pH of solutions prepared by students (developed in the Greenaway lab by Dr. Liam Welch), saves time on tedious tasks.

Future plans

“I don’t think we’re going to stop now, are we?” says Becky. In the Greenaway lab, the process of automation is now second nature. As their research becomes more autonomous, integrations have allowed the team to create singular workflows, combining Opentrons and other commercial equipment.

Use of the OT-2, and automation, has only expanded since Becky was one of the first to bring an Opentrons liquid handling robot to the department. Both OT-2 and Flex robots are used across the chemistry department and in other automation spaces, like ROAR and ATLAS, and other research labs. Becky is the Co-Director of ROAR and serves on the management team for these facilities, which cover small molecule and materials synthesis all the way up to battery development. She also closely collaborates with the Advanced Hackspace, where the postgraduate lab is hosted, for custom prototyping.

Colleagues and collaborators continue to reach out for help with automating specific processes in their own labs, and there’s room for growth in the classroom too. Whatever comes next, it’s clear that tomorrow’s chemists will need automation in the lab. Thanks to the hard work of Becky Greenaway, Annabel Basford, and Sean Gurung, students at Imperial College London can use Opentrons technology to learn critical skills today.