For scaling up and fully automating magnetic bead-based plasmid extraction and purification

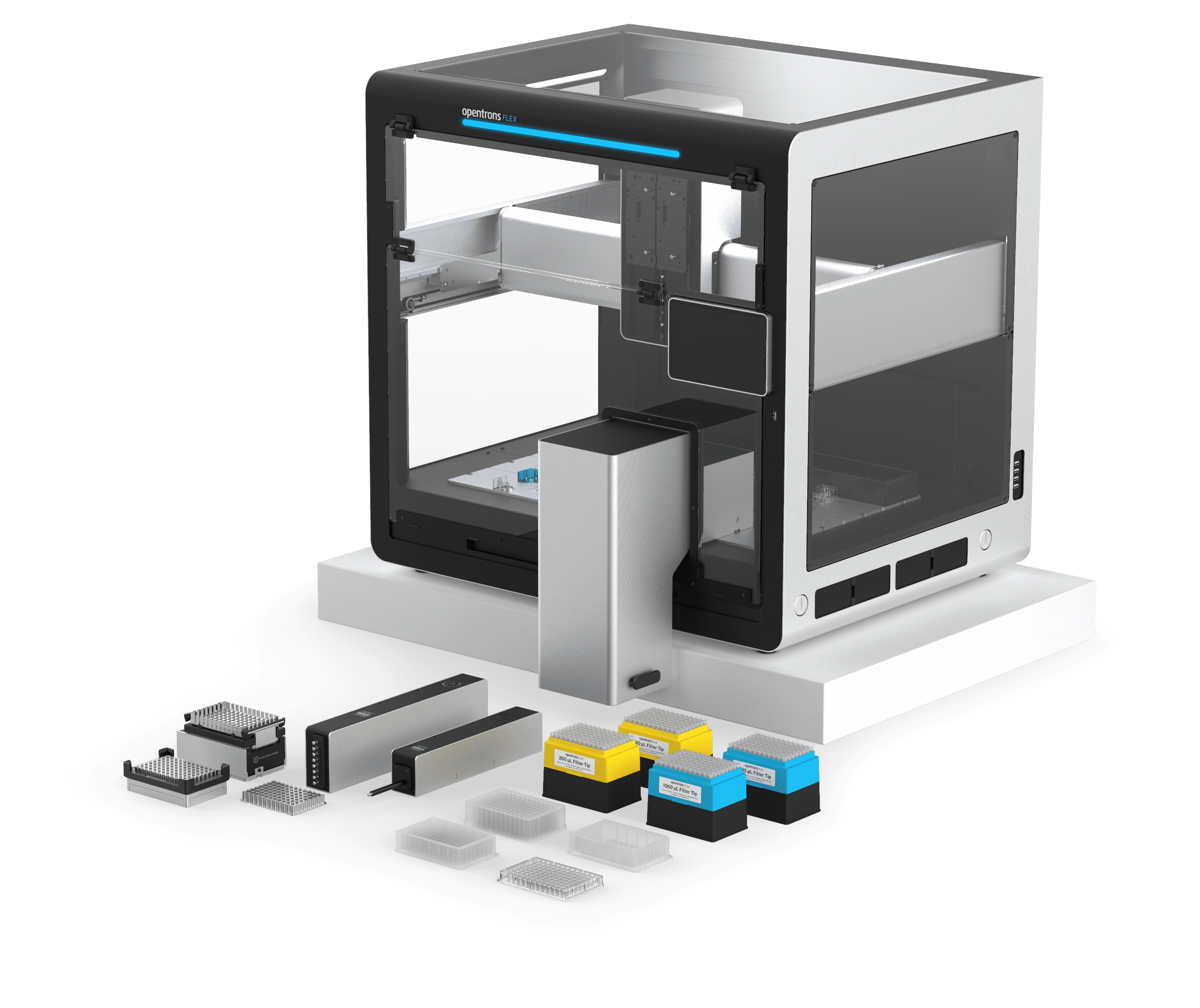

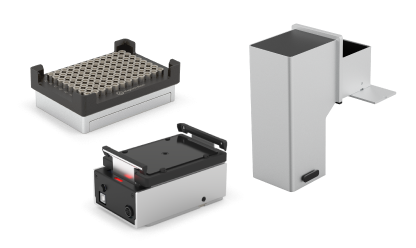

The Opentrons Flex Plasmid Prep Workstation includes the Flex Robot, Pipettes, Tips, Labware, Magnetic Block, Heater-Shaker, Waste Chute, and Remote Protocol Development.

With the Flex Plasmid Prep Workstation, you can automate your magnetic bead-based plasmid extraction and purification workflows. This workstation is equipped with high-volume pipettes, Heater-Shaker Module, and Magnetic Block to accommodate for most bead-based chemistry. Protocol development is included with the workstation to ensure the Flex is ready to run soon after installation.

The Flex Plasmid Prep Workstation can support the following workflow steps:

Bacterial cell lysis

Magnetic bead separation

The Flex Plasmid Prep Workstation is configured with hardware, consumables, and custom protocol development for your assay.

For FAQs about the OT-2 and Opentrons Flex, click here.

You do not need to know how to code to use the Opentrons Flex platform. Protocols can be created using Opentrons’ plug-and-play protocol design tools. We also have an Applications Engineering team that can build custom protocols for you.

The Opentrons Flex requires on-site installation. We also offer both remote and on-site services solutions, as well as annual preventative maintenance.

You can find more information on Opentrons’ service offerings here.

Yes. Just like the OT-2, the Flex has full capability to accept custom or irregular labware. Our custom labware creation tools can be used to help create the compatible labware definitions that are required to use irregular labware with our software.

Users do not need a computer connected to the Opentrons Flex to run a protocol. Users will need to build the protocol on a computer and upload it to the Flex. Once uploaded, the protocol can be ran solely off the display.

No, Opentrons’ OT-2 pipettes will not be compatible with the Opentrons Flex. The Opentrons Flex is intended for use with our Flex Pipettes.

Yes, the Opentrons Flex’s side windows and front door are removable.

Crashes will be detected by the Opentrons Flex by comparing the actual vs. intended move of the embedded motors.

For example, If the robot expected 2 motor rotations, but only 1 rotation is completed due to a crash(which stops the motors from moving), then the robot would detect a discrepancy between intended move and actual. This would then throw an error and let you know you need to recalibrate.

You can use one computer running the Opentrons App to connect to multiple robots. This is true for both the Opentrons Flex and OT-2 robots.

Users can save up to 8 protocols to the Opentrons Flex display.

20 cm (8 in) of side and back clearance for cables, USB connections, and to dissipate exhaust from instruments like the Thermocycler or Temperature Module.